2025 How to Optimize Corrugated Packaging Solutions for Your Business

In today’s competitive marketplace, the pursuit of efficiency and cost-effectiveness is paramount for businesses across various industries. One of the most impactful areas where companies can achieve significant improvements is through the optimization of their corrugated packaging solutions. Corrugated packaging not only serves as a protective barrier for products during transit but also plays a critical role in branding and sustainability efforts. As consumer preferences shift towards environmentally friendly options, the importance of innovative corrugated packaging solutions has never been more pronounced.

By focusing on the strategic development and implementation of these packaging methods, businesses can enhance their operational efficiencies, reduce waste, and improve customer satisfaction. This introduction sets the stage for a deeper exploration of how optimizing corrugated packaging solutions can drive success, streamline logistics, and ultimately lead to a more sustainable business model. As we delve into the strategies and best practices for maximizing the effectiveness of these solutions, it is crucial to recognize the multifaceted benefits they offer, from cost savings to enhanced product protection and brand representation.

Understanding the Importance of Corrugated Packaging in Business

Corrugated packaging plays a crucial role in the business landscape, serving as both a protective vessel for products and a powerful branding tool. Understanding its importance allows businesses to enhance their logistics, minimize costs, and improve customer satisfaction. The lightweight yet sturdy nature of corrugated materials ensures that products are well-protected during transportation, reducing the risk of damage and returns. This reliability translates into a solid reputation for businesses, fostering trust among consumers.

Tips for optimizing your corrugated packaging include assessing your product sizes and weights to determine the right box specifications. Custom-sized packaging can save space and material costs while ensuring products are secure during transit. Additionally, consider implementing eco-friendly materials in your packaging solutions. Not only can this lower your environmental impact, but it also caters to an increasingly eco-conscious customer base.

Another important aspect is the design of the packaging itself. Eye-catching graphics and branding can turn a simple box into a marketing tool, capturing customers’ attention from the moment it arrives. Incorporate clear, informative labeling, which can enhance the unboxing experience and keep your brand top of mind. By focusing on these elements, businesses can leverage corrugated packaging to drive growth and improve overall product presentation.

2025 Corrugated Packaging Solutions Optimization

This chart illustrates the optimization factors of corrugated packaging solutions and their importance levels for businesses in 2025. Key dimensions such as cost reduction, sustainability, supply chain efficiency, branding impact, and customer satisfaction are vital for enhancing operational effectiveness.

Assessing Your Current Packaging Needs and Challenges

Assessing your current packaging needs and challenges is crucial for optimizing

corrugated packaging solutions in your business. As per the Smithers Pira report, the global

corrugated packaging market is projected to reach a value of $280 billion by 2025.

This growth highlights the increasing importance of sustainable and efficient packaging solutions that meet both industry standards and customer expectations.

Businesses must evaluate their operational requirements, such as product dimensions, weight limitations, and shipping processes, to ensure their packaging strategy

is aligned with these market trends.

To effectively assess packaging challenges, companies should conduct a thorough analysis of existing packaging materials and methods.

According to a survey by Packaging Strategies, over 60% of manufacturers reported difficulties with packaging waste and supply chain inefficiencies.

Identifying specific pain points, such as excessive material usage or logistical setbacks, can unveil opportunities for enhancement.

Transitioning to smarter designs or innovative materials can reduce costs and environmental impact, allowing businesses to stay competitive in an evolving marketplace.

By prioritizing a robust assessment process, businesses can tailor their corrugated packaging solutions to resolve obstacles and meet their operational goals.

Exploring Innovative Materials and Designs for Corrugated Packaging

In recent years, the corrugated packaging industry has witnessed a significant transformation driven by the need for sustainability and efficiency. According to a report by Smithers, the global corrugated packaging market is expected to reach $290 billion by 2025, indicating a growing demand for innovative solutions. Businesses today are looking beyond traditional designs and materials to optimize their packaging processes. Emphasizing the use of innovative materials such as recycled content and biodegradable options can not only reduce environmental impact but also enhance brand image, as consumers are increasingly favoring eco-friendly products.

Moreover, advancements in design technology, such as digital printing and 3D modeling, are allowing companies to create unique packaging solutions tailored to specific products. The adoption of minimalist design principles combined with functional features, like easy-to-handle structures and enhanced protection, contribute to improved customer satisfaction and reduced shipping costs. A report from the Freedonia Group highlights that the demand for corrugated boxes is projected to grow by 3.6% annually through 2023, further underscoring the urgency for companies to invest in innovative packaging strategies. By embracing these materials and designs, businesses can not only streamline their operations but also position themselves competitively in a rapidly evolving market.

2025 How to Optimize Corrugated Packaging Solutions for Your Business - Exploring Innovative Materials and Designs for Corrugated Packaging

| Aspect | Description | Benefits | Innovative Materials | Design Strategies |

|---|---|---|---|---|

| Durability | Strength and resistance to various shipping conditions | Reduces damage, lower replacement costs | High-performance flutes | Reinforced corners |

| Sustainability | Use of recyclable and biodegradable materials | Improves brand image, meets consumer demand | Recycled paperboard | Minimalist design |

| Customization | Tailored designs for specific products | Enhances protection and brand identity | Custom die-cuts | Unique structural designs |

| Cost Efficiency | Minimizing material usage without compromising quality | Lowers shipping costs, increases margins | Lightweight materials | Optimized dimensions |

| Shelf Appeal | Aesthetically pleasing designs that attract consumers | Increases sales and brand recognition | Eco-friendly inks | Vibrant graphics |

Implementing Cost-Effective Strategies for Packaging Optimization

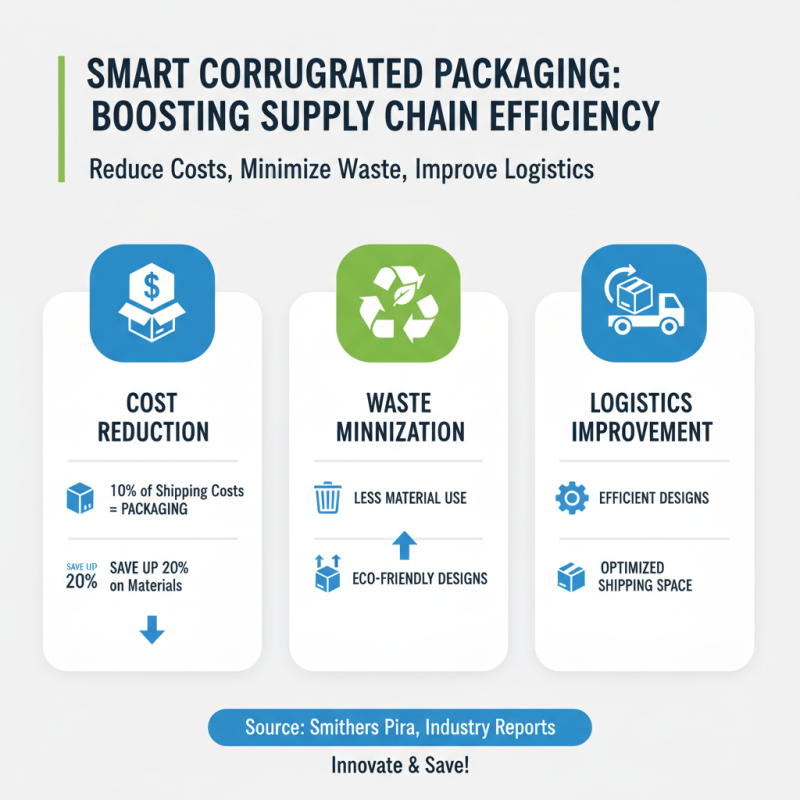

As businesses strive to enhance their supply chain efficiencies, optimizing corrugated packaging solutions has become essential. Industry reports indicate that packaging accounts for nearly 10% of total shipping costs, making it a critical area for cost reduction. Implementing cost-effective strategies in packaging optimization not only lowers expenses but also minimizes waste. According to a study by the Smithers Pira, adopting more efficient packaging designs can save companies up to 20% in material costs while improving logistical efficiencies.

One overlooked area is the choice of materials and design. By switching to lightweight, high-strength corrugated materials, businesses can reduce shipping weights significantly. Additionally, optimizing the packaging size and reducing excess material can lead to lower shipping costs, as dimensional weight pricing becomes a vital factor in shipping expenses. The Packaging Machinery Manufacturers Institute (PMMI) reports that more than 35% of manufacturers are re-evaluating their packaging processes to focus on sustainability and cost-effectiveness, highlighting a growing trend in the industry.

Moreover, technology plays a crucial role in optimizing packaging solutions. Automated packaging systems and predictive analytics can analyze product dimensions and optimize packaging designs accordingly, thereby reducing material waste and improving production speeds. As per the National Association of Manufacturers (NAM), companies that implement such technological solutions can see a return on investment of up to 300%. This integration not only streamlines operations but also aligns with consumer expectations for more sustainable packaging, ultimately enhancing brand reputation and customer satisfaction.

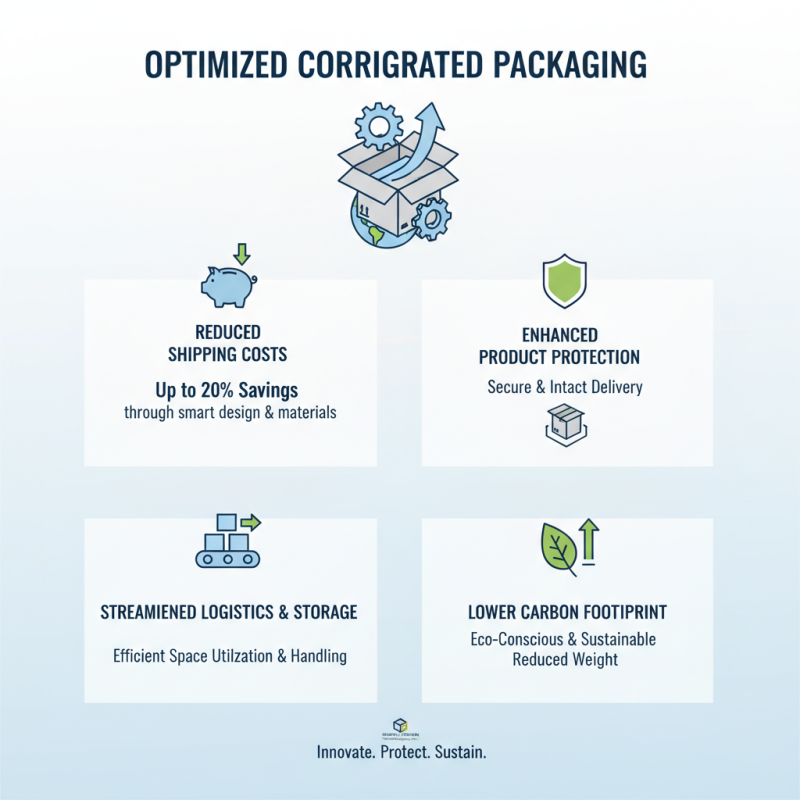

Measuring the Impact of Optimized Packaging on Supply Chain Efficiency

Optimizing corrugated packaging solutions is crucial for enhancing supply chain efficiency. Research indicates that businesses can reduce shipping costs by up to 20% through the use of optimized packaging designs and materials. The right packaging not only protects products but also streamlines logistics and storage, contributing to overall operational efficiency. By implementing innovative designs, companies can ensure maximum use of space, minimize weight, and ultimately lower carbon footprints, which is increasingly important in today's eco-conscious market.

Tips for optimizing your packaging include evaluating your current packaging processes and materials. Consider conducting a lifecycle assessment to measure the environmental impact of your packaging choices. According to a study by the Sustainable Packaging Coalition, sustainable packaging can improve brand perception and customer loyalty while reducing material costs. Additionally, utilizing data analytics can help identify inefficiencies in the supply chain related to packaging, enabling targeted improvements.

Another effective approach is collaborating with suppliers to innovate packaging solutions. A report by Smithers PIRA highlights that packaging innovation can result in a 15% increase in supply chain performance. Engaging with suppliers not only promotes new ideas but can lead to cost savings by leveraging shared resources and expertise. Adopting these strategies can significantly enhance your business's packaging efficiency and contribute positively to the supply chain ecosystem.

Related Posts

-

10 Essential Tips for Effective Packaging Products That Boost Sales

-

How to Choose the Best Business Packaging for Your Brand Success

-

Top 10 Innovative Packaging Design Trends to Watch in 2023

-

Top 10 Stunning Packaging Design Trends You Need to Know in 2023

-

2025 How to Choose the Best Arrow Packaging Solutions for Your Business

-

Quality Packaging Trends to Watch in 2025 for Top Digital Products